Description

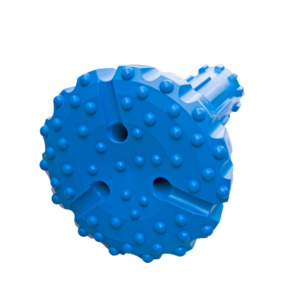

DTH drill bits are widely used in the construction industry to produce piles into rock, also water wells, and drilling bores for geothermal ground source heat pumps. Our DTH bits can provide a easier service even in a hard condition. DTH hammer bit is connected with impactor by spline of bit body, guides and rotates for impacting and transferring, and breaking rocks.

Description

| DHD3.5 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weigh(kgs) | ||

| Gauge | Front | ||||||

|

Flat face | 90 | 6xΦ14 | 5xΦ12 | 2 | 4.7 | |

| Flat face | 95 | 6xΦ14 | 5xΦ12 | 2 | 4.8 | ||

| Flat face | 100 | 6xΦ14 | 6xΦ12 | 2 | 4.9 | ||

| Flat face | 108 | 8xΦ13 | 6xΦ12 | 2 | 5.4 | ||

| DHD340 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weight(kgs) | ||

| Gauge | Front | ||||||

|

Convex face | 108 | 7xΦ16 | 6xΦ14 | 2 | 7.85 | |

| Convex face | 115 | 7xΦ16 | 6xΦ14 | 2 | 8.22 | ||

| Convex face | 127 | 8xΦ16 | 4xΦ14+3xΦ13 | 2 | 8.88 | ||

| Convex face | 130 | 8xΦ16 | 4xΦ14+3xΦ13 | 2 | 9.15 | ||

| DHD350 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weight(kgs) | ||

| Gauge | Front | ||||||

|

Convex face | 140 | 7xΦ18 | 4xΦ15+3xΦ14 | 2 | 15.8 | |

| Flat face | 146 | 8xΦ18 | 8xΦ14 | 2 | 16.5 | ||

| Flat face | 152 | 8xΦ18 | 8xΦ14 | 2 | 17 | ||

| Concave Face | 165 | 8xΦ18 | 4xΦ16+4xΦ14 | 2 | 18.9 | ||

| Concave Face | 178 | 8xΦ18 | 6xΦ16+5xΦ14 | 2 | 20.4 | ||

| DHD360 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weight(kgs) | ||

| Gauge | Front | ||||||

|

Concave Face | 154 | 8xΦ18 | 4xΦ16+4xΦ15 | 2 | 22.5 | |

| Flat face | 165 | 8xΦ18 | 8xΦ16 | 2 | 23.6 | ||

| Concave Face | 171 | 8xΦ18 | 6xΦ16+4xΦ15 | 2 | 25.2 | ||

| Concave Face | 178 | 8xΦ18 | 6xΦ16+5xΦ15 | 2 | 26.1 | ||

| Concave Face | 190 | 9xΦ18 | 6xΦ16+5xΦ15 | 2 | 29 | ||

| Concave Face | 203 | 10xΦ18 | 8xΦ16+6xΦ15 | 2 | 30.4 | ||

| DHD380 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weight(kgs) | ||

| Gauge | Front | ||||||

|

Hammer Sec |

Concave Face | 203 | 10xΦ18 | 4xΦ18+10xΦ16 | 2 | 48.5 | |

| Concave Face | 216 | 10xΦ18 | 4xΦ18+10xΦ16 | 2 | 52.1 | ||

| Concave Face | 230 | 12xΦ18 | 12xΦ18+6xΦ16 | 2 | 54.8 | ||

| Concave Face | 235 | 12xΦ18 | 12xΦ18+6xΦ16 | 2 | 55.5 | ||

| Concave Face | 254 | 12xΦ18 | 12xΦ18+8xΦ16 | 2 | 62.4 | ||

| Concave Face | 275 | 12xΦ18 | 27xΦ16 | 2 | 69 | ||

| Concave Face | 305 | 15xΦ18 | 35Φ16 | 3 | 77.6 | ||

| DHD1120 Drill Bit | |||||||

| Shank Type | Face shape | Head Diameter (mm) |

No x Buttons dia mm | Air holes | Weight(kgs) | ||

| Gauge | Front | ||||||

|

Concave Face | 305 | 15xΦ20 | 27xΦ18+8xΦ16 | 3 | 141.3 | |

| Concave Face | 311 | 15xΦ20 | 27xΦ18+8xΦ16 | 3 | 141.6 | ||

| Concave Face | 325 | 15xΦ20 | 27xΦ18+9xΦ16 | 3 | 164.3 | ||

| Concave Face | 350 | 16xΦ20 | 32xΦ18+13xΦ16 | 4 | 169.1 | ||

| Concave Face | 381 | 16xΦ20 | 36xΦ18+18xΦ16 | 4 | 183 | ||

| Concave Face | 400 | 16xΦ20 | 40xΦ18+28xΦ16 | 4 | 194 | ||

| Concave Face | 445 | 20xΦ20 | 48xΦ18+25xΦ16 | 4 | 225.7 | ||

| Concave Face | 500 | 24xΦ20 | 90xΦ18 | 4 | 331.2 | ||

Customized Service

Choice of bit face

| Drop Center | Concave Face | Convex Face | Flat Face | Double Gauge Face |

|

|

|

|

|

| Suitable for high penetration rates and minimal hole deviation in soft to medium-hard and fractured rock formations. | Suitable for all ground applications, especially medium-hard and homogeneous rock formations. Offers good hole deviation control and excellent flushing capacity. | Suitable for soft to medium-hard rock formations with low to medium air pressures. Highly resistant to steel wash, reduces load and wear on gauge buttons, offers high penetration rates but poor hole deviation control. | Suitable for very hard and abrasive rock formations with high air pressures, offering good penetration rates and resistance to steel wash. | Suitable for high air pressure drilling in medium to hard rock formations, designed for high penetration and good steel body resistance. |

Choice of buttons’ shape

| Spherical Button | Parabolic Semi-Ballistic Buttons |

Ballistic Button | Sharp Ballistic Button | |

|

|

|

|

|

| Buttons typically serve as gauge buttons on DTH bits, designed for highly abrasive and hard formations. | Buttons are commonly used as gauge buttons and front buttons on DTH bits, suitable for moderately abrasive and hard formations. | Buttons are typically used as front buttons on DTH bits, suitable for moderately abrasive and moderately hard formations. They can also function as gauge buttons in softer rock. | Buttons are commonly used as front buttons on DTH bits for soft formations, ensuring fast penetration rates and a low risk of button breakage. |

Competitive Advantage

1:Top grade carbide tungsten with fast drilling speed and long life.

2::Fine Steel ensures fine metallographic structure and great strength.

3:Detailed mechanic process avoids premature failure.

4:Sophisticated heat treatment ensures great hardness and abrasiveness.

Application

Faster penetration speed in the mine&Higher stability during construction